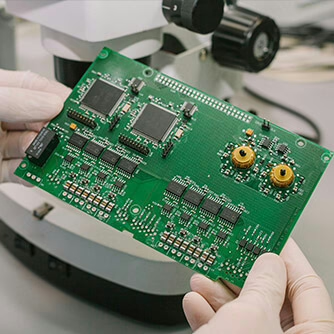

This offers comprehensive placement and solderability error detection at an impressive speed of your SMT and PCB assembly.

BGA checks are performed using an ErsaScope, which allows optical inspection under the device. We also offer x-ray as a service, if required.

Through-hole inspection is assisted by the use of a Yestech comparator system which allows rapid checking of device orientation and value.

In addition, our experienced team of inspectors carry out PCB board inspections and visual checks to IPC standards.

We are also able to carry out a functional PCB test on your PCBA or finished product according to your test procedure.

If required, we are happy to facilitate direct connection of your test equipment to your network.

We welcome a joint approach to testing and are happy to discuss your test requirements.

AOI tests performed on a single SOIC alone

Maximum magnification of our ErsaScope endoscopic inspection system

Typical AOI test time taken per component

A finished PCB board should be compared to the design documents and/or a working prototype to ensure that it meets specifications and has no differences.

An optical inspection uses an automated camera (AOI) or an experienced worker to look at a circuit board and compare it to the original design.

An automated camera captures the image of the PCB, which is then sent to image analysis software that compares the PCB in the photograph to an established standard. If there are differences, the board is reported as defective to the operator.

“We have enjoyed an excellent commercial and technical relationship for 20 years with Camtronics. They have supported us in manufacturing and in continuously developing competitive products that keep us at the forefront of the industrial and automotive industry.”

Global industrial sensor & control company

“Throughout our ten-year partnership, we have always valued Camtronics’ commitment to flexibility and communication.

Their collaborative and proactive approach is a major benefit to us and we value the high quality of the increasing number of products they manufacture on our behalf”

Leading UK bio-pharma company

“Camtronics have handled small, one-off panel sample orders right through to large scale production volume orders … and deliveries have always been met.

Communication is a key aspect for us and we have entered into a strong working relationship, one that will hopefully last for a long time.”

Market leading industrial processing company

“We have been testing the ESC’s that you produced for us, and I am very happy to say that we have had zero rejects (Yes, that’s zero! Issues, faults or any trouble at all!). Honestly outstanding.

Technical Director

Safety, protection & compliance company